The foundation is the most critical structural element of any building, serving as the base that transfers building loads to the ground. In Central Texas, where soil conditions can be challenging, selecting the right foundation type is essential for long-term structural integrity. This comprehensive guide explores the main foundation types used in residential and commercial construction throughout the Killeen, Temple, and Central Texas region, helping you make an informed decision for your project.

Understanding Foundation Systems

A building foundation serves three primary functions: supporting structural loads, isolating the building from ground moisture, and providing stability against soil movement. The right foundation type depends on soil conditions, building requirements, local climate, and budget considerations.

Load Distribution

Foundations must distribute the building's weight evenly to prevent settlement or structural failure. This includes dead loads (building weight), live loads (occupants and furniture), and environmental loads (wind, snow, or seismic activity).

Moisture Management

Proper foundations prevent water infiltration that can cause mold, mildew, and structural damage. This includes managing groundwater, surface water runoff, and vapor transmission through the slab.

Soil-Structure Interaction

Central Texas soils are dynamic, expanding when wet and contracting when dry. Foundations must accommodate these movements without transferring cracks to the building above.

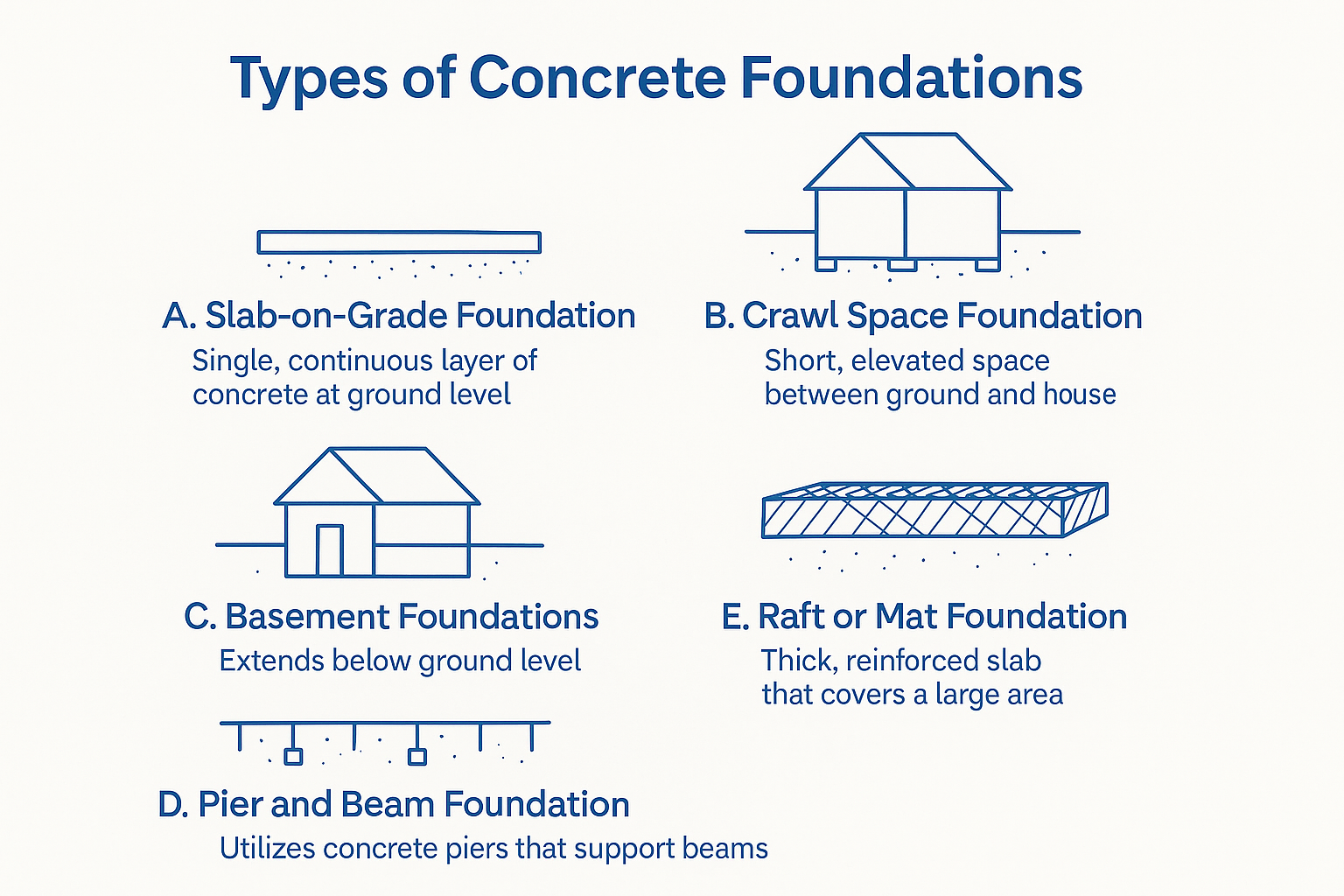

Slab-on-Grade Foundations: The Texas Standard

Slab-on-grade foundations are the most common foundation type in Central Texas, accounting for approximately 80% of residential construction. This foundation consists of a concrete slab poured directly on the ground, typically 4-6 inches thick with thickened edges (grade beams) around the perimeter.

Construction Process

The slab-on-grade construction process involves several critical steps:

Site Preparation

- Excavation: Remove topsoil and organic material to reach stable subsoil

- Grading: Level the site to ensure proper drainage away from the building

- Soil Compaction: Compact the subsoil to prevent future settlement

- Base Course: Install gravel or crushed stone base for drainage and support

Foundation Construction

- Vapor Barrier: Install 6-10 mil polyethylene sheeting over the base

- Edge Insulation: Rigid foam boards around perimeter for energy efficiency

- Reinforcement: Steel rebar or wire mesh for tensile strength

- Formwork: Temporary forms to contain the concrete during pouring

Concrete Placement and Finishing

- Concrete Delivery: Ready-mix concrete delivered at proper slump

- Placement: Concrete placed and spread evenly across the forms

- Consolidation: Vibrators remove air pockets and ensure proper density

- Strike-off and Finish: Surface leveled and smoothed

Reinforcement Strategies

Proper reinforcement is crucial for slab performance:

- Wire Mesh: 6x6 inch welded wire fabric for general reinforcement

- Rebar: Individual steel bars for concentrated loads or special conditions

- Fiber Reinforcement: Synthetic fibers for crack control and impact resistance

- Post-Tensioning: High-strength cables for large commercial applications

Control Joints and Expansion

Control joints are planned cracks that prevent random cracking:

- Saw Cuts: Made 24-48 hours after concrete placement

- Depth: Cut ¼ to ⅓ the slab thickness

- Spacing: Every 10-15 feet depending on slab thickness

- Sealing: Filled with flexible sealant for waterproofing

Advantages of Slab-on-Grade

- Cost-Effective: Lowest construction cost per square foot

- Energy Efficient: No crawl space to condition, reducing heating/cooling costs

- Pest Resistant: Fewer entry points for rodents and insects

- Low Maintenance: Fewer components to maintain or repair

- Fast Construction: Can be completed in days rather than weeks

Limitations and Considerations

- Soil Movement: Susceptible to cracking from expansive soils

- Moisture Issues: Can wick moisture if not properly sealed

- Repairs Difficult: Major repairs require breaking up large concrete sections

- Utilities: Harder to access plumbing and electrical lines

Best Applications

Slab-on-grade foundations work well for:

- Level building sites with stable, well-draining soil

- Small to medium residential homes (under 3,000 sq ft)

- Commercial buildings with simple floor plans

- Areas with low water table and minimal frost potential

- Buildings without basements or extensive below-grade requirements

Pier and Beam Foundations: Traditional Texas Choice

Pier and beam foundations (also called post and beam) have been used in Texas for over a century. This system consists of concrete piers or columns that support wooden beams, creating a raised floor system with a ventilated crawl space beneath.

System Components

The pier and beam system includes several key components:

Concrete Piers

- Depth: Extend 4-8 feet below grade, depending on soil conditions

- Diameter: 12-24 inches for residential, larger for commercial

- Reinforcement: Steel rebar for structural integrity

- Base: Bell-shaped footing for load distribution

Support Beams

- Materials: Pressure-treated lumber or engineered wood products

- Size: 2x8 to 2x12 depending on span and load requirements

- Connectors: Steel brackets and joist hangers for secure connections

- Treatment: Preservatives protect against decay and insects

Floor Joists and Subfloor

- Joists: Span between beams, typically 2x8 or 2x10

- Spacing: 16 inches on center for standard applications

- Subfloor: Plywood or OSB sheeting, ¾ inch minimum thickness

- Fastening: Ring shank nails or screws for durability

Construction Process

Pier and beam construction follows a systematic approach:

- Site Layout: Mark pier locations and beam alignments

- Pier Excavation: Dig holes for concrete piers

- Form Installation: Set forms for pier construction

- Pier Pouring: Place concrete piers with reinforcement

- Beam Installation: Attach beams to pier anchors

- Joist Installation: Install floor joists between beams

- Subfloor Installation: Attach plywood or OSB sheeting

- Crawl Space Finishing: Install vapor barriers and drainage

Crawl Space Considerations

The crawl space beneath pier and beam foundations requires proper finishing:

- Vapor Barrier: 6-10 mil plastic sheeting over soil

- Drainage: Perforated pipe and gravel for water removal

- Ventilation: Foundation vents for air circulation

- Insulation: Optional for energy efficiency

- Access: Removable panels for maintenance and inspection

Advantages of Pier and Beam

- Soil Adaptation: Can accommodate expansive clay soils better than slabs

- Accessibility: Easy access to plumbing, electrical, and HVAC systems

- Ventilation: Natural airflow reduces moisture and mold issues

- Foundation Repair: Individual components can be replaced without major demolition

- Sloping Sites: Better suited for uneven terrain than slab foundations

- Historical Significance: Traditional Texas construction method

Maintenance Requirements

- Inspection: Annual crawl space inspection for moisture and pests

- Ventilation: Keep vents clear and functional

- Wood Treatment: Periodic application of wood preservatives

- Drainage: Maintain proper grading and drainage systems

Deep Foundations: Engineered Solutions

In areas with poor soil conditions, high water tables, or heavy structural loads, deep foundations may be necessary. These systems transfer building loads to deeper, more stable soil layers or bedrock.

Driven Pile Foundations

Steel or concrete piles driven deep into the ground:

- Materials: Steel H-piles, pipe piles, or precast concrete piles

- Installation: Hydraulic hammers or vibratory drivers

- Capacity: Can support hundreds of tons per pile

- Applications: Heavy commercial buildings, bridges, high-rises

Drilled Shaft Foundations

Large diameter concrete columns drilled deep into the ground:

- Diameter: 2-10 feet depending on load requirements

- Depth: 20-100+ feet to reach stable soil or bedrock

- Reinforcement: Steel rebar cages for structural integrity

- Applications: Heavy structures, seismic zones, poor soil conditions

Caisson Foundations

Watertight structures for construction in wet or unstable conditions:

- Types: Pneumatic caissons (with compressed air) or open caissons

- Applications: Bridge piers, underwater structures

- Advantages: Can be installed in flowing water or soft soils

Foundation Selection Factors

Several factors influence the choice of foundation type:

Soil Conditions

- Expansive Clays: Require foundations that can accommodate movement

- Sandy Soils: May require deeper foundations for stability

- High Water Table: Affects foundation depth and waterproofing needs

- Soil Bearing Capacity: Determines foundation size requirements

Building Requirements

- Structural Loads: Heavy buildings need stronger foundations

- Utility Requirements: Some systems allow easier utility access

- Future Expansion: Consider potential additions or modifications

- Aesthetic Preferences: Some homeowners prefer raised floors

Site Characteristics

- Topography: Sloping sites may favor pier and beam systems

- Accessibility: Equipment access affects construction feasibility

- Environmental Factors: Protected areas may have restrictions

- Utility Conflicts: Existing underground utilities must be considered

Economic Considerations

- Initial Cost: Slab foundations are typically least expensive

- Maintenance Costs: Pier and beam may require more upkeep

- Energy Efficiency: Slab foundations generally use less energy

- Resale Value: Local preferences affect market value

Central Texas Soil Considerations

Central Texas soils present unique challenges that must be addressed in foundation design:

Expansive Clay Soils

The region's clay-rich soils can swell up to 10% when wet, causing significant foundation movement:

- Soil Classification: CH (high plasticity clay) in many areas

- Expansion Potential: Can exert pressures up to 5,000 psf on foundations

- Depth of Influence: Active zone extends 8-15 feet below grade

- Weather Dependency: Droughts cause shrinkage, rains cause swelling

Variable Soil Conditions

Soil types can change dramatically within short distances:

- Geologic Formations: Edwards Plateau, Blackland Prairie, Balcones Fault Zone

- Soil Surveys: NRCS soil maps help identify local conditions

- Test Borings: Essential for large projects to verify soil conditions

- Site-Specific Analysis: Each building site requires individual evaluation

Weather and Climate Effects

- Drought Conditions: Extended dry periods cause significant soil shrinkage

- Heavy Rainfall: Rapid water absorption leads to soil swelling

- Seasonal Variations: Soil moisture content fluctuates throughout the year

- Construction Timing: Optimal construction during stable moisture periods

Foundation Engineering and Design

Professional engineering is essential for proper foundation design:

Soil Investigation

- Test Borings: 2-3 borings per 2,000 sq ft for residential projects

- Soil Classification: Laboratory testing for engineering properties

- Groundwater Levels: Monitoring of water table fluctuations

- Settlement Analysis: Prediction of foundation movement

Structural Calculations

- Load Analysis: Dead, live, wind, and seismic loads

- Foundation Sizing: Based on soil bearing capacity and safety factors

- Settlement Criteria: Allowable settlement limits for different building types

- Factor of Safety: Minimum 2.0 for most foundation designs

Construction Documents

- Foundation Plans: Detailed drawings showing all components

- Reinforcement Details: Bar sizes, spacing, and lap lengths

- Material Specifications: Concrete strength, reinforcement grade

- Quality Control: Testing and inspection requirements

Construction Quality and Inspection

Proper construction and inspection ensure foundation performance:

Quality Control Measures

- Concrete Testing: Slump, air content, and strength testing

- Reinforcement Inspection: Proper placement and cover requirements

- Compaction Verification: Soil density testing beneath foundations

- Elevation Surveys: Ensure proper grading and drainage

Local Building Inspections

- Foundation Inspection: Before concrete placement

- Concrete Inspection: During and after placement

- Final Inspection: Before backfilling or framing

- Special Inspections: For engineered foundations

Foundation Maintenance and Repairs

Regular maintenance extends foundation life and prevents costly repairs:

Preventive Maintenance

- Drainage Systems: Keep gutters, downspouts, and drains clear

- Grading: Maintain proper slope away from foundation

- Vegetation: Control plants near foundation to prevent root damage

- Moisture Control: Monitor for leaks and high humidity

Common Foundation Problems

- Cracks: Hairline cracks are normal; wide cracks indicate problems

- Settlement: Uneven settling can cause structural damage

- Water Intrusion: Can cause mold, mildew, and structural decay

- Pest Infestation: Termites and rodents can damage wood components

Making the Right Choice

Selecting the right foundation requires careful consideration of all factors:

When to Choose Slab-on-Grade

- Budget is a primary concern

- Site has stable, well-draining soil

- Building is relatively small and simple

- Energy efficiency is important

When to Choose Pier and Beam

ul>When Deep Foundations Are Needed

- Soil conditions are extremely poor

- Building loads are very heavy

- Site has high water table

- Seismic considerations apply

Consult with a local foundation expert to determine the best foundation type for your specific site conditions. Professional engineering and local contractor expertise are essential for long-term structural integrity and peace of mind.

Remember that while foundation costs represent a significant portion of total construction expenses, they are the most critical investment in your building's longevity and safety. Choose wisely, and your foundation will support your building successfully for generations to come.